COMPANY PROFILE

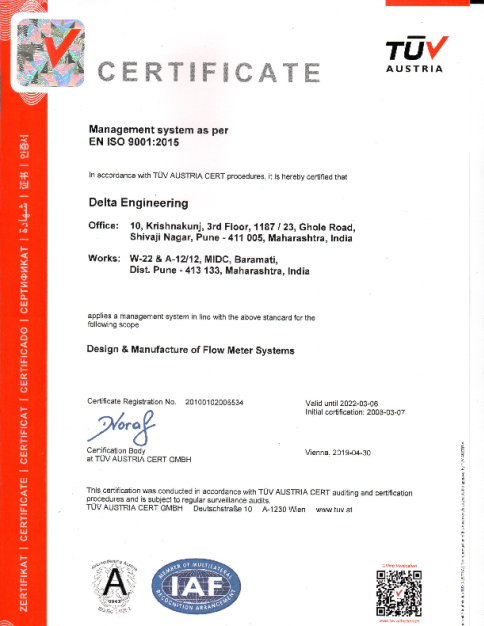

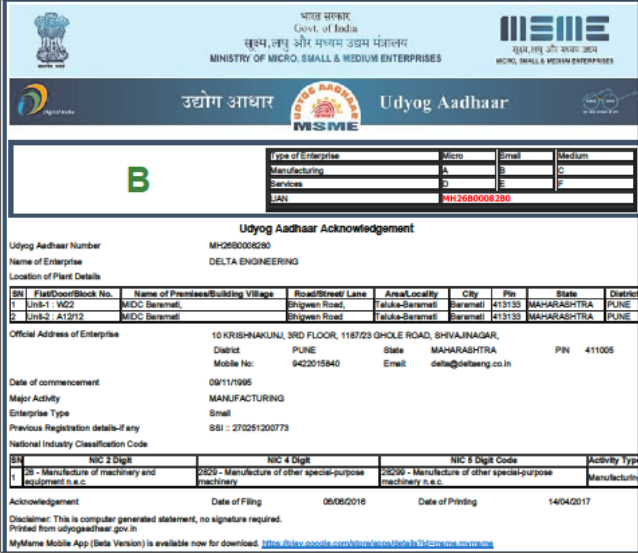

DELTA ENGINEERING commenced its operations with a business objective of Design and

Manufacture of Flow Elements and Instrumentation and Control System Services to Core

Process Industries like Chemical, Petrochemical, Sugar & Beverages and Power Industries

in the country in September 1995.

“Delta Engineering has a state of art manufacturing facility at Baramati with work space area

of 7000 sq.ft having 10 ton overhead crane, inverter based Kemppi welding machines,

CNC’s, etc. to supply quality products to our customers”.